This is a high-quality AB/AB Italian Panguaneta Poplar Plywood sheet (laserply) that is suitable for a wide range of applications and is particularly suited to laser cutting. Panguaneta manages its own woodlands, so it knows that every last sheet has been produced responsibly, sustainably, and to the highest of standards. This Poplar Plywood has an AB/AB grading which is typically the best grade of plywood available.

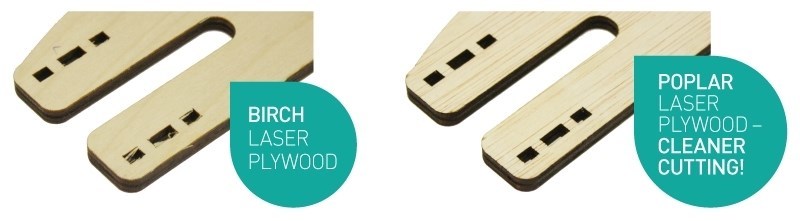

Poplar has a lower density than Birch, meaning that it can be easily laser cut at lower power settings (See comparison image below).

Please note:

As wood is a natural product, there is often a crook or bow to the sheet. The natural twist might be in excess of 25mm (see below – Tolerances and Caution).

The material’s surface will be consistent in appearance with some possible colour variations. May contain sound-tight knots no larger than 35mm in diameter; small knotholes or hairline cracks, only if well patched. Small glue marks, repairs and well-filled patches are also allowed.

This plywood uses an EN314-2 Class 1 glue which is suitable for Interior (dry) conditions. Interior glue is generally considered the preferred option for materials that are to be laser cut. This is because the exterior glues can cause a more obvious ‘burnt’ look on and around the area that is cut.

Poplar is a cultivated wood that grows quickly, which makes it a very sustainable product.

Features:

- High-quality poplar laser plywood sheets (laserply).

- Low density for easier laser cutting.

- Interior grade glue.

Contents:

- 1 x 3mm Poplar Laser Plywood (laserply), 600mm x 400mm Sheet.

Dimensions:

- Length: 600mm.

- Width: 400mm.

- Height: 3mm.

Video:

Watch this video below for information on how to use this product (please note: other Kitronik products are included in this video).

Tolerances:

The manufacturing tolerance for the thickness of plywood sheets are the stated thickness +0.2mm/-0.4mm. This means a 3mm plywood sheet could be between 2.6mm and 3.2mm in thickness.

Resources:

Caution:

- As wood is a natural product there is often a bow or crook to plywood, and in some cases a twist. We have measured in excess of 25mm rise between the flat centre of the plywood and the corner. These twists are completely normal and add to the natural character of the plywood. If you are using this product on a laser cutter; these sheets should be strapped/taped to the laser bed before cutting.

A Hayes –

We received these this year, usually order Birch ply, but none in stock so we ordered these, and 80% of them are warped in the middle which makes it very difficult to use them on the laser cutter. Hopefully, the birch will be in stock again next year.

geoffhampson –

Thank you for your review. Unfortunately the Poplar Plywood sheets have been discontinued due to sourcing issues in Russia and we don’t have a date as to when we may be able to get this material again.

In regards to the warp you are seeing on the Poplar Plywood sheets, this is quite normal for this material. Some amount of the warp you are seeing is likely caused by the sheet absorbing moisture during transit. Depending on where and how they are being stored they can need some time to reacclimatise and you will likely see a lot of the warp drop out. Often you will see a difference over about 48 hours if they are next to a radiator or in an environment like an airing cupboard. If all of the warp does not drop out of the sheet pinning is your most effective option from there, when we work with these sorts of materials we use neodymium magnets and a honey comb bed. If you don’t have a honey comb bed then tall thin weights are probably your best option.

Thank you again for your review. If you require any assistance please don’t hesitate to contact us.

Kitronik Ltd.

KP –

We love this product, its really easy to laser cut. Product is even better than birch plywood.